Guanke Technology is a manufacturer that focuses on the research, development and sales of cannabis plant lights. The temperature requirements of cannabis vary with the type of cannabis. The temperature for cannabis cultivation should be about 28 degrees Celsius, but should not exceed 32 degrees Celsius, nor should it below 10 degrees Celsius. The temperature difference should be prevented from rising and falling more than 10 degrees Celsius, because the temperature difference will affect the growth of plants. If the temperature exceeds 32 degrees Celsius, the buds will be fluffy and produce very little THC. If the temperature drops below 17 degrees Celsius, the plants will stop growing, the stems will turn purple, and the flower buds will grow slower and will not grow. But strangely, low temperatures actually made marijuana produce more THC.

The relative humidity should be kept between 50% and 60%. If vegetatively propagated in another room, cabinet or pot, keep the humidity at 80% because the vegetatively propagated cannabis has not yet taken root. Remember not to exceed 60% humidity during the growing and blooming period as the carbon filter will be severely damaged. On the other hand, too low humidity can strongly destroy the harvest. If possible, put in a steamer to improve humidity. The humidity should be as low as possible in the later stages of the harvest to prevent the buds from rotting. Warmer temperatures can increase carbon dioxide in the air. It is best to keep the temperature moderate so that a high THC yield can be obtained. If the temperature is too high, although the buds are relatively large, the quality will be reduced.

Cannabis uses

Internationally, the type of hemp with a THC content of less than 0.3% is called industrial hemp, which is mainly divided into medicinal industrial hemp and fiber industrial hemp. So far, the European Union and Canada have legally stipulated that hemp with a plant THC content of less than 0.3% is industrial hemp. Industrial hemp has no drug use value, and is promoted by government-licensed cultivation. In recent years, due to its special medicinal value, cannabis has become a hot crop, especially the demand for medicinal ingredient CBD is increasing year by year, and the production demand is increasing day by day. Studies have shown that CBD is not only non-addictive, but can cure many difficult conditions, such as epilepsy, Alzheimer’s disease, anxiety, pain and inflammation. In addition to medicinal uses, CBD can also be used in food, beverages, cosmetics and health products, with huge market demand and potential profits. Based on the above reasons, the cultivation area of cannabis has continued to increase under the conditions permitted by law, especially the indoor cultivation area has increased significantly, and the supply capacity has been enhanced.

Status of Industrial Hemp

Industrial hemp is a crop suitable for indoor cultivation or plant factory production, and the Netherlands and Belgium are the largest indoor hemp producers in Europe.

Cannabis is a high value-added crop that can be grown profitably in a controlled environment with a fully electric light source.

Plant factory cultivation has many advantages, ensuring high-quality, high-yield, stable and annual continuous production of industrial hemp plants.

Specifically, it includes the following points:

① The growth factors are automatically controllable, including the supply of water and fertilizer, the regulation of environmental factors (light, CO2 concentration, temperature and humidity, etc.), and the seedling and planting time.

② Indoor and efficient cannabis cultivation will not compete with main crops for land resources, saving land resources;

③ Avoiding weeds, pests, weather disasters, continuous cropping obstacles and other troubles, avoiding the pollution of pesticides, heavy metals and other chemicals or pollutants ;

④ Factory production management greatly improves production efficiency and reduces labor intensity and labor;

There are also deficiencies in the cultivation of cannabis in plant factories, including the following points:

① There is a lack of special varieties, and special industrial hemp varieties suitable for plant factory cultivation should be accelerated to improve the production efficiency of CBD;

② The planting technology is high in content and requires high-quality technicians;

③ The cost of electricity consumption for indoor cultivation accounts for a large proportion of the production cost. Industrial hemp is a light-loving, short-day crop, and late-maturing varieties are more sensitive to light, so when growing industrial hemp in a greenhouse, special attention should be paid to the lighting conditions;

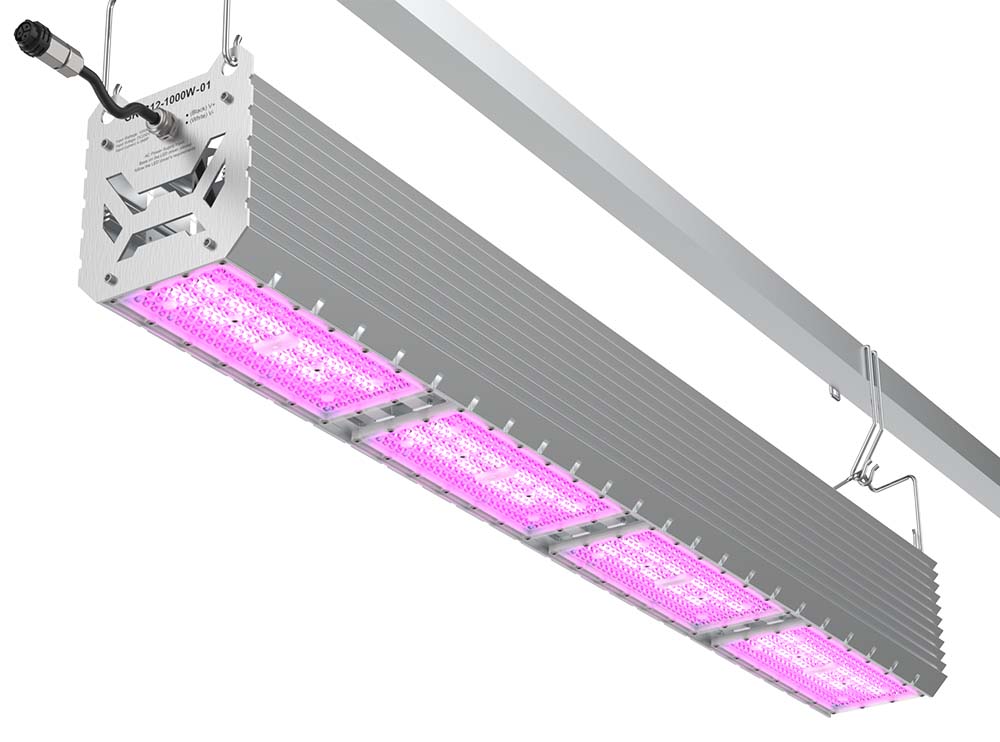

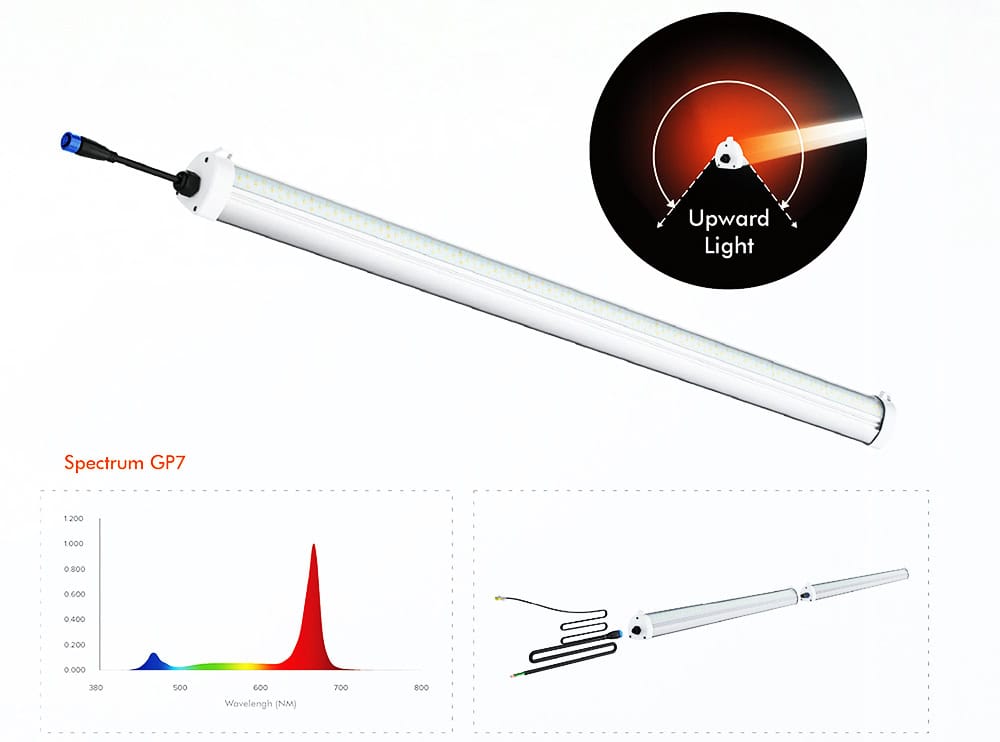

④ There is a lack of special hydroponic or matrix culture systems and LED lighting systems and environmental control systems. system equipment. Hemp is a light-loving short-day plant, which is sensitive to light conditions and environmental conditions. The regulation of growth factors can change the content of THC and CBD in industrial hemp. Therefore, using the regulation of growth factors to increase the content of active ingredients in cannabis plants will become a commonly used safe and efficient method. To this end, industrial hemp farmers and researchers around the world are interested in increasing CBD production by trying various methods of environmental factor regulation. Among them, light environment regulation is one of the most important regulation methods. The use of LED light sources for indoor cannabis cultivation is a good high-yield approach. The light source has the advantages of energy saving, long life, and the dynamic and intelligent control of the light environment.

Plant factory is a relatively mature facility horticultural production method, which has been widely used in the factory production of leafy vegetables, root vegetables, strawberries, medicinal plants, etc. Therefore, on the basis of facility cultivation technology, industrial hemp can completely realize plant factory production. However, compared with horticultural crops, industrial hemp has unique morphological characteristics, physiological characteristics and unique product organs. Therefore, the plant plant cultivation system design, environmental factor regulation strategy, LED lighting system, etc. of industrial hemp are different from those of horticultural crops.

Special technical equipment must be developed to meet the needs of efficient production of industrial hemp. Plant factory cultivation is an effective way to improve the quality and efficiency of industrial hemp production. Therefore, exploring the cultivation methods to promote the accumulation of CBD has become an important research goal for the high-quality and efficient cultivation and production of medicinal industrial hemp. In order to realize the efficient cultivation of industrial hemp plants, it is necessary to carry out systematic technical research, and to study the common technologies and key technologies of biological learning and regulation of industrial hemp cultivation. High biological yield and CBD are obtained through specific technical regulation, and the THC content is controlled at legal levels.

The specific technical requirements are as follows:

① Create a foundation for the high quality and high yield of industrial hemp from a genetic perspective through breeding innovation, and determine the dynamic change characteristics of cannabinoid content in each growth period;

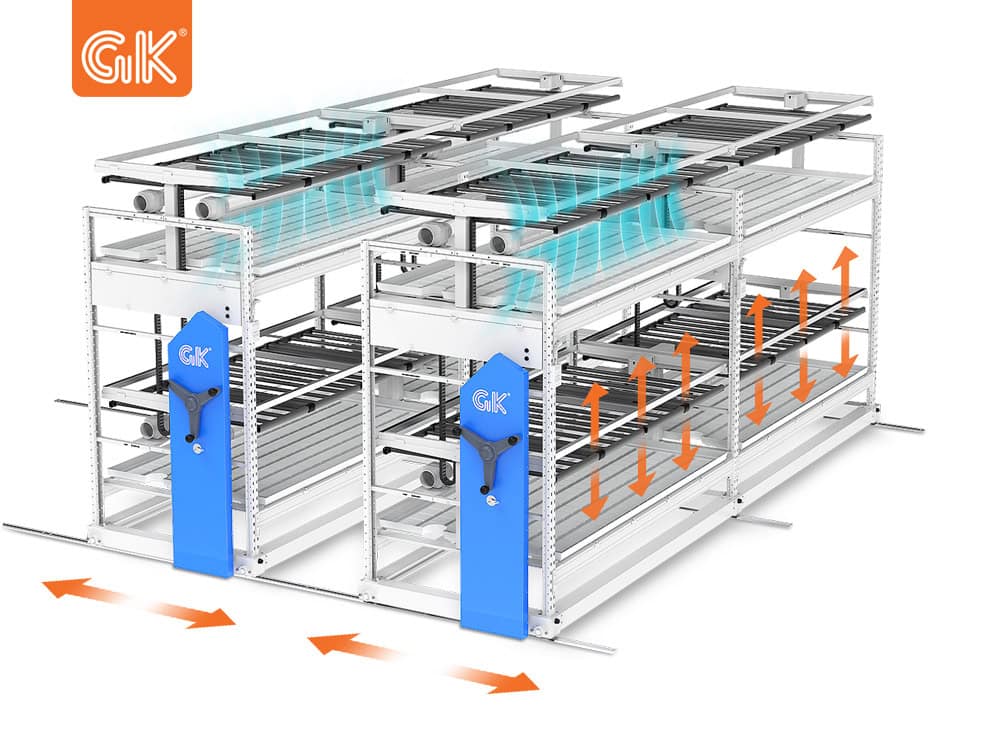

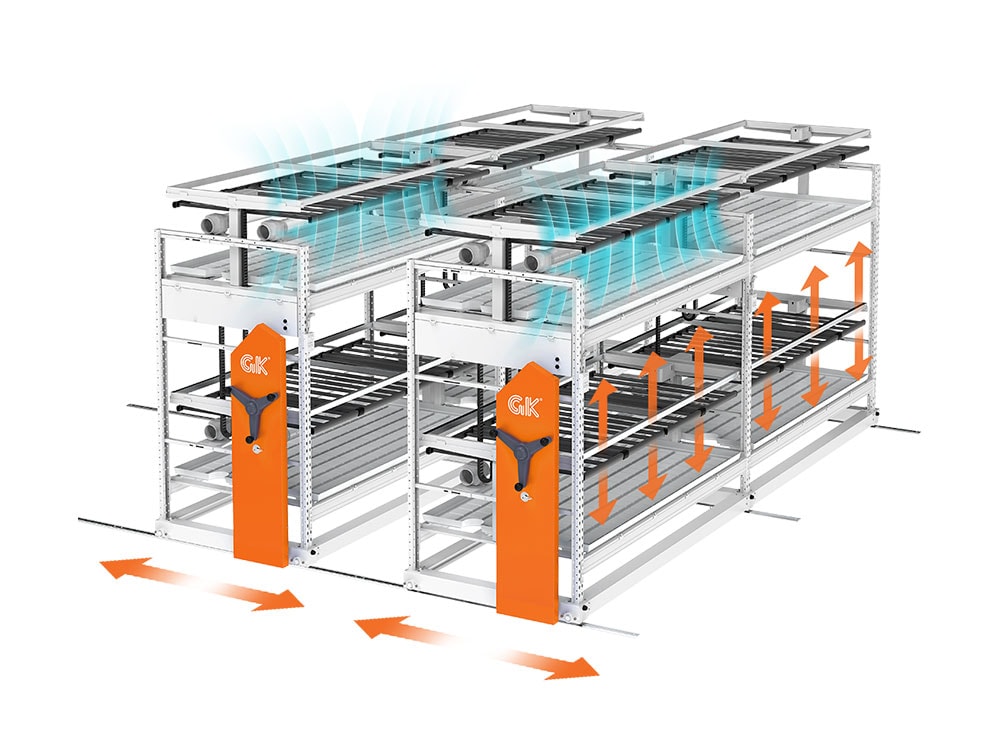

② Develop a special cultivation system for industrial hemp cultivation in plant factories, including substrate culture or hydroponic equipment ;

③ The research and development of LED lighting system and environmental control system is the key point. The biggest advantage of cannabis cultivation in plant factories is that the environment is controllable.

Through the regulation of growth factors such as light and nutrition, the physiological process of cannabis plants can be fully mobilized to promote growth, increase CBD content, and control THC content. LED lighting system is the most important technical requirement, efficient LED lighting system can not only save the cost of initial installation, but also realize energy-saving production. At present, industrial hemp LED lamps are the most demanded products in the world. It is urgent to optimize and improve the design of hemp LED lamps on the basis of fully investigating the photobiological laws of cannabis plants, to achieve the optimal spectrum and optimal control strategy, and to achieve high-efficiency and energy-saving production. to satisfy the market’s needs.