Lighting is one of the most critical factors influencing the success of indoor cannabis cultivation. As cultivators aim for consistent quality, higher yields, and energy efficiency, understanding how to design an optimized lighting system becomes essential. This guide explores the core principles of effective lighting design tailored to cannabis growing environments.

1. Understand the Cannabis Light Spectrum Requirements

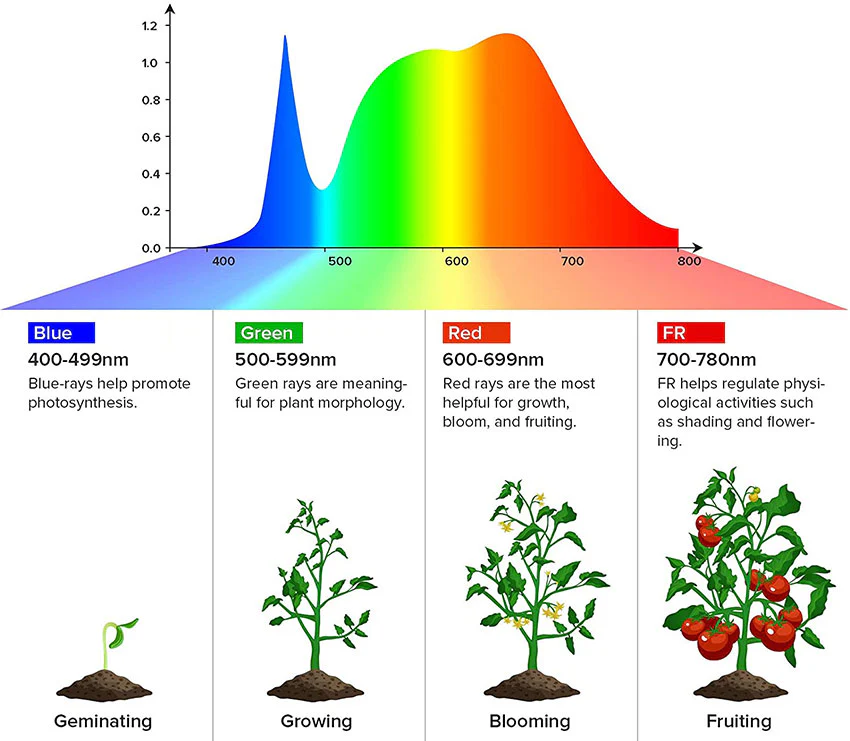

Cannabis responds uniquely to different wavelengths throughout its growth cycle. While blue light (400–500nm) supports vegetative development, red light (600–700nm) plays a major role during flowering. A full-spectrum LED grow light that balances both regions—along with supplemental far-red and UV—can enhance cannabinoid production, improve morphology, and reduce growth time.、

Recommended Spectral Strategy:

Vegetative Phase: Blue dominant, 4000–5000K CCT

Flowering Phase: Red dominant, 3000–3500K CCT + far-red (730nm)

Optional Enhancements: UV-A (360–400nm) for trichome stimulation

All of our horticultural grow lights offer customizable spectra tailored to specific crop types. Contact us for more details.https://www.gkhorti.com/product/g68-01-greenhouse-interlighting/

2. Focus on Light Uniformity and Distribution

Uneven light distribution causes inconsistent plant growth and reduces overall canopy efficiency. High-quality cannabis grow lights must maintain a uniform PPFD (Photosynthetic Photon Flux Density) across the grow area, ideally within ±10% variation. Uniformity depends on both fixture design and room layout.

Best Practices:

Use wide-beam LED bars for better canopy coverage

Maintain proper fixture height (typically 12–24 inches from canopy)

Consider inter-canopy lighting for dense grow setups

Our grow lights deliver a high efficacy of 3.8 µmol/J, enabling higher yields with greater energy efficiency.https://www.gkhorti.com/product/g67-top-led-lighting-solution/

3. Optimize DLI (Daily Light Integral) and PPFD

Cannabis plants require a high DLI to reach peak productivity, especially during flowering. A typical target is DLI of 30–60 mol/m²/day, achievable with a PPFD of 600–1000 μmol/m²/s for 12 hours per day.

Fixture Design Tip:

Ensure the light can deliver the required PPFD at target mounting heights

Enable dimming (0–10V or smart control) to fine-tune light intensity throughout the growth cycle

4. Thermal Management and Efficiency

LEDs are highly energy-efficient, but poor thermal design can reduce lifetime and performance. A cannabis-specific fixture should use aluminum heatsinks or active cooling to maintain optimal operating temperatures.

Efficiency Metric:

Target PPF efficacy: ≥2.5 μmol/J

Rated lifespan: ≥50,000 hours (L90 or L70 standard)

Our grow lights deliver a high efficacy of 3.8 µmol/J, enabling higher yields with greater energy efficiency.https://www.gkhorti.com/product/g67-top-led-lighting-solution/

5. Integrate with Smart Controls and Cultivation Systems

Modern cannabis facilities benefit from dynamic lighting controls—scheduling, dimming, and real-time spectrum adjustment—to meet different strain requirements and improve energy savings.

Integration Suggestions:

0–10V dimming interface or wireless control systems

Photoperiod scheduling for precise light/dark cycles

Environmental sensors for automated responses

Conclusion

Designing the ideal lighting system for cannabis cultivation requires more than just brightness—it demands a thoughtful approach to spectrum, intensity, uniformity, and integration. At [Your Company Name], we develop high-performance grow lights engineered specifically for cannabis, delivering the perfect balance of technology and plant science to help cultivators thrive.

Contact us https://www.gkhorti.com/contact/to learn how our cannabis lighting solutions can elevate your grow operation.